Back to overview │ GMO deburring tool │ GMO deburring cutter │ GMO Lollipop │ GMO HSF-Tool

GMO deburring cutter

The GMO deburring cutters not only impress with their very good cutting values, but also with their universal applicability.

In connection with a GMO-DATA NC program, curved bore edges, bore edges with center offset and asymmetrical contours can be deburred without any problems, even without the use of CAM systems.

Your advantages at a glance:

- with cutting angles of 45 ° and 25 ° ideal for every application

- ideal for deburring curved hole edges

- high quality carbide tool with special coating

- extremely long service life

- can be used from a bore diameter of 1.5 mm

- large range of tools

optionally with NC data set for difficult contours

Our wide range of standard tools is rounded off by our high flexibility in the manufacture of special solutions.

Application examples

With the help of a GMO-DATA NC program, curved or asymmetrical hole edges can be deburred in addition to flat hole edges.

Milling types and dimensions

The GMO deburring cutters are available in internal deburring or internal and external deburring designs. Both versions are available with different cutting angles.

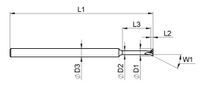

GMO deburring cutter for internal deburring

45° range

25° range

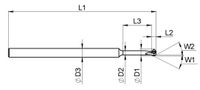

GMO deburring cutter for internal and external deburring

45°/45° range

25°/45° range

Application advantages of the deburring cutter with 25 ° cutting angle

Milling cutter with 45° cutting angle

The hole ratio is sufficiently large. Despite the curvature, the bore can be deburred with a 45° milling cutter.

Milling cutter with 45° cutting angle

The hole ratio is smaller. This causes the cutter with a 45° cutting angle to damage the contour.

Milling cutter with 25° cutting angle

The flatter angle creates more free space, which means that the hole can be deburred without damaging the contour.

Cutting angle B cutting edge 45°

The front cutting edge has a standard cutting angle of 45°. Even with a 25° inner cutting edge.

GMO-DATA

CNC data set suitable for your application!

With the help of a 3D model or a component drawing, a CNC program is created individually for the contour to be deburred.

The GMO deburring cutters can also be used to cleanly deburr curved or asymmetrical contours.

You will receive the finished contour data record and only need to insert it into the existing production program.

GMO deburring cutter + GMO-DATA = an unbeatable team!

Downloads

You can find application notes and examples here.